2. Dyeing Process

Hanking (HANK) Bagging

The hanks (HANK) produced in the pretwisting factory, when placed directly into the dyeing vat, can be affected by the movement of water necessary for dyeing. This can lead to disruptions in the yarn flow and shape, making it challenging to proceed to the next stage. To prevent interference with dyeing, the hanks are packed into bags made of materials that do not hinder the dyeing process, preparing them for dyeing.

To the Dyeing Vat

1. Moving to the Dyeing Vat

To help you visualize the internal structure of the dyeing vat, we’ve included an image of a household pasta pot, which has a similar structure.

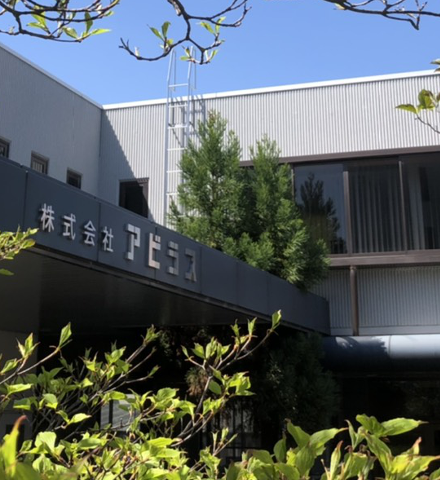

The actual dyeing vat, seen in the workplace photo, is considerably large compared to the buckets around it. The size of this dyeing vat is small to medium.

The hank-filled bags are placed inside the inner pot and submerged in water.

Due to the size, which is impractical for manual lifting, a machine is used to lift and introduce the hanks into the dyeing vat.

Introducing hanks into the dyeing vat. It’s not uncommon to dye 200 kg of hanks in a single dyeing session.

2. Drying of Dyed Hanks

The dyed hanks are removed from the dyeing bags, arranged at regular intervals on a belt conveyor-type large drying machine, ensuring even drying. By the time they come out of the conveyor, the drying process is complete. The dried hanks are then packed into dedicated boxes in specific quantities and sent to the next stage, the winding process factory.