Dope-dyed polyester yarn

Table of Contents

a. Outstanding Color Fastness

b. High-Quality, Uniform Fibers

2. Advantages of Our Dope dyed yarn LEI

a. LEI Significantly Reduces Environmental Impact

b. Color Fastness of LEI

c. LEI’s 303 Colors and Delivery

3. LEI Features, Materials, Yarn Count Quick Reference

1. What is Dope dyed yarn ?

a) Properly known as new dye method yarn

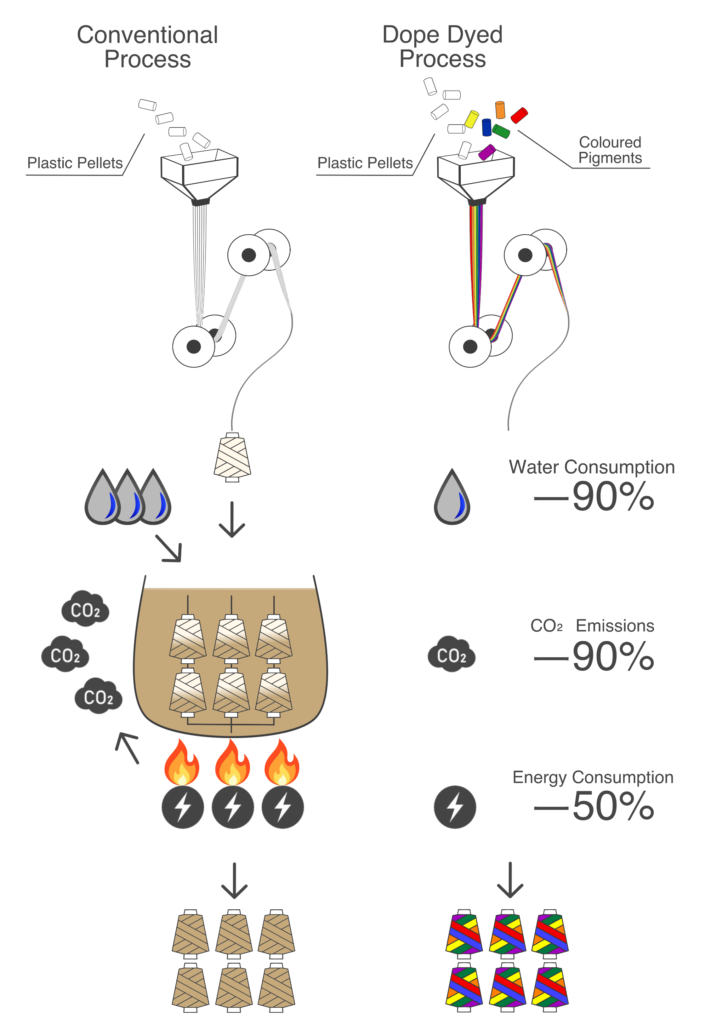

In conventional polyester yarn production, the raw material (polyester pellets) is melted and spun, followed by the dyeing process. Dope dyed yarn, however, incorporates pigments or dyes during the melting and spinning process. This skips the traditional dyeing process,

leading to substantial reductions in:

– Water consumption

– Energy consumption

– CO₂ emissions

b) Outstanding Color Fastness

Think back to childhood days of mixing multiple colors of clay until they blend into a single color. Using a similar method, pigments or dyes are kneaded into the yarn during production.

c) High-Quality, Uniform Fibers

Skipping the dyeing process, which often involves substantial water usage, results in high-quality and uniform fiber products.

Yarn is surprisingly delicate, and it can degrade due to processes involving human touch and environmental changes. During the dyeing process, the yarn is immersed in cold water and subjected to heat to reach the high temperatures necessary for dyeing. After dyeing, the temperature decreases to a level where people can touch the yarn, and the soaked yarn is placed in a drying machine.

These are typical stresses and damages incurred by yarn in the dyeing process. However, this is not the case with the dope dyed yarn. While it might not be easily visible when looking at the yarn alone, the advantage of dope dyed yarn is that it results in less damage reflected in the final products such as garments and fabrics.

2. Advantages of Our Original Dyed Yarn LEI

a) LEI Significantly Reduces Environmental Impact

In the manufacturing process of our dope dyed yarn LEI, our in-house estimates indicate a reduction of:

– Water consumption by -90%

– CO₂ emissions by -90%

– Energy consumption by -50%

b) Color Fastness of LEI

LEI exhibits high color fastness across washing, sweat exposure, sublimation, light exposure, and friction, ensuring reliability in various conditions.

c) LEI’s 303 Colors and Delivery

LEI offers stock sales of 303 colors, a leading range in Japan. Regular colorfastness tests are conducted for all colors to ensure consistent quality. Simultaneously, LEI provides customers with fast and cost-effective delivery methods.

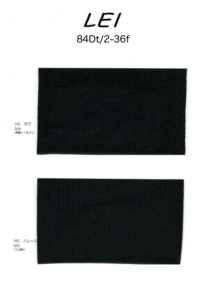

3. LEI Features, Materials, Quick Reference

| Name |

LEI |

| Feature |

Reduce Environmental Impact Polyester Yarn– Water consumption -90%– CO2 emissions -90%– Energy consumption -50%– High quality color fastness |

| Material |

100% polyester |

| Thickness (Dt) |

84Dt/2-36f |

| By order color quantity |

20 kg~ |

| Retail size |

800 g / 1 cone |

| Color stock |

301 colors |

*Please note.

There may be differences between the colors you see on the web (on your computer monitor) and the actual colors.

The color samples (colorbook) featured on this page are intended for reference purposes only. For accurate color matching, please use our actual colorbook.