Resistance to yellowing nylon yarn

Table of Contents

- What is Yellowing – Common Causes

- Oxidation by Sebum or Sweat

- Oxidation due to Light (UV)

- Reaction with NOx Gas

- TUNE WHITE Evidence

- Cortrous Test

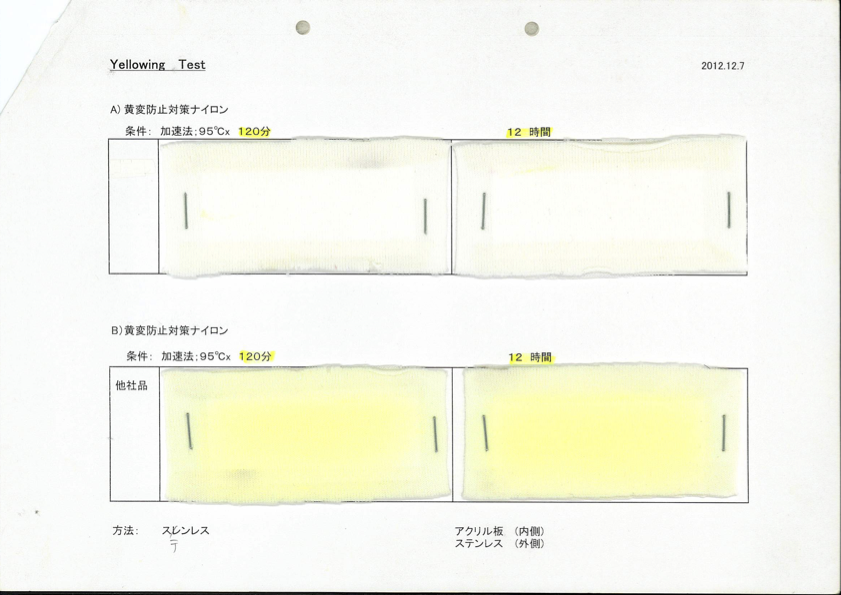

- JIS L 0855 Test (Comparison of 95°C for 2 Hours and 12 Hours)

- Yellowing Comparison Test for A&B Trials

- TUNE WHITE Features, Materials, Quick Reference

1. What is Yellowing – Common Causes

– Fiber yellowing refers to the discoloration of fibers, commonly caused by sebum, sweat, or fat residues left on clothing around the armpits or collar. When left in contact, these substances oxidize in the presence of oxygen in the air, resulting in a yellowish tint. Other causes include the reaction between nitrogen oxide gases (NOx) and antioxidants present in vinyl or plastic materials, leading to yellowing.

– Yellowing is not exclusive to nylon; it can occur in various fiber products, including natural fibers like cotton, silk, wool, and synthetic fibers like spandex. In blended yarn or fabrics, partial or complete yellowing of blended fibers may occur. The mechanisms of typical yellowing in nylon are explained in sections a to c below.

a. Oxidation by Sebum or Sweat :

When sebum or sweat is left untreated, it oxidizes upon exposure to oxygen in the air, leading to yellowing. This is particularly prone to happen around collars, armpits, and cuffs.

b. Oxidation due to Light (UV) :

Extended exposure to light (UV radiation) causes oxidation of nylon fibers, resulting in yellowing. This usually occurs in areas exposed to light.

c. Reaction with NOx Gas :

NOx gases are a collective term for nitrogen oxide compounds generated when things burn at high temperatures. In the atmosphere, compounds like NO, NO2, N2O, N2O3 exist. Yellowing can occur when NOx gases react with BHT (butylated hydroxytoluene), an antioxidant. BHT is used in vinyl bags, plastic products, rubber products, machine oil, adhesives, polyurethane foam, and more. It can come in contact with fibers through sublimation, reacting with NOx gases, leading to yellowing. Similarly, the breakdown of lignin, a natural phenolic compound generated from wood, can result in yellowing through a similar process.

* 昇華(しょうか、英語:sublimation)は、元素や化合物が液体を経ずに固体から気体、

または気体から個体へと相転移する現象。後者については凝華(ぎょうか)ともいう。

2. TUNE WHITE Evidence

– Despite variations in natural and chemical fibers, yellowing issues persist in the fiber product market. While adding anti-yellowing agents to products before market release is common, problems continue. The yellowing problem is deep-seated, often becoming a critical issue for companies.

– In our AVILAS PLUS, the anti-yellowing nylon “TUNE WHITE” utilizes a yellowing inhibitor that differs from traditional ones. It employs a unique agent that avoids the impact of NOx gases entirely. This dramatically resolves distribution issues, providing a groundbreaking solution that is more cost-effective and offers higher efficacy than conventional processes. The following explains the evidence supporting the anti-yellowing effect of our “TUNE WHITE.”

Test Methods

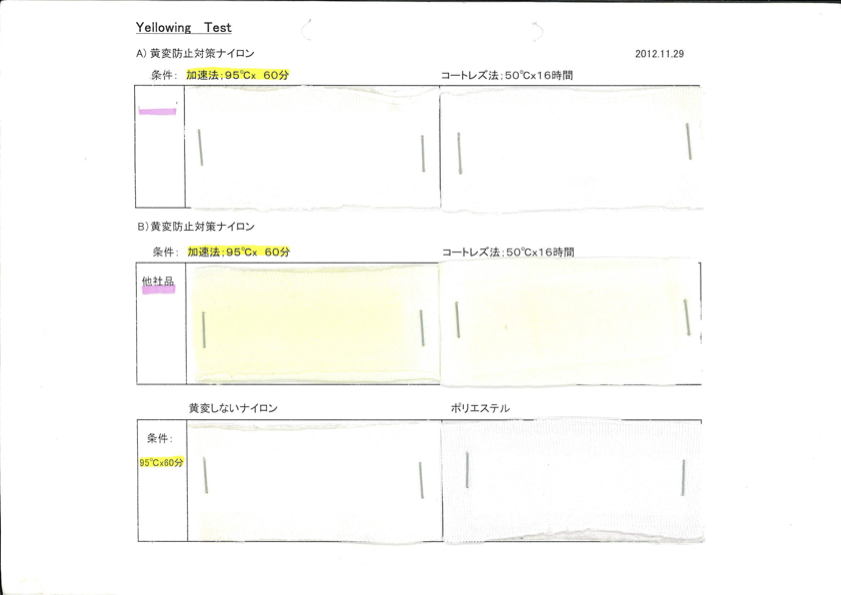

- JIS L 0855 “Dyeing Fastness Test Against Nitrogen Oxide” :

Place the test specimen with standard dyed fabric into the test device, inject nitrogen oxide gas, and maintain a constant temperature and dry conditions. When the standard dyed fabric discolors, remove the test specimen, treat it with buffered urea solution, and assess the degree of color change in the test specimen.

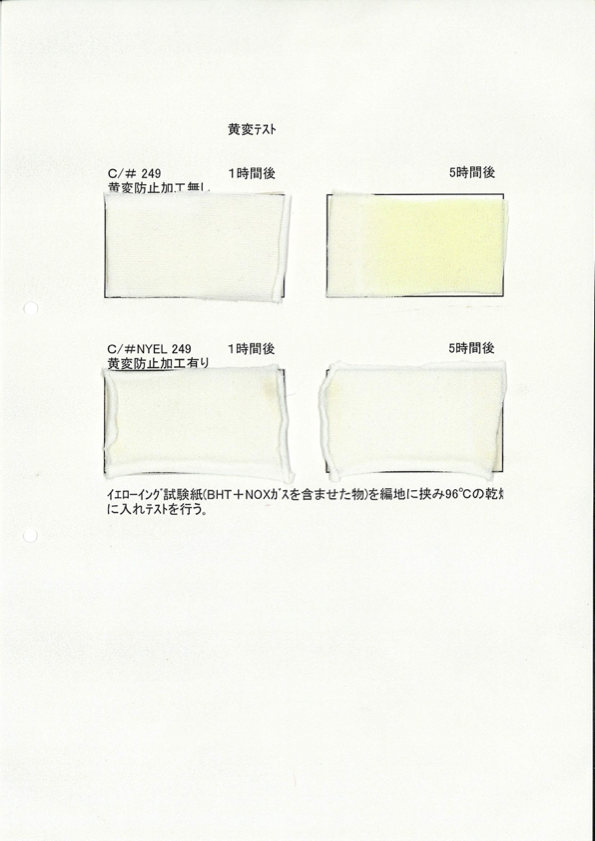

- Cortrous Yellowing Test (Yellowing Test using Yellowing Test Paper) :

This test is an alternative to the JIS L 0855 test, which cannot measure the influence of BHT (butylated hydroxytoluene) – a frequently problematic element in yellowing. Use yellowing test paper (paper containing BHT and NOx gas) and place it in close contact with the test specimen in a constant temperature dryer at 50°C. After 15 hours with added weight, assess the degree of yellowing.

– **Comparison of Yellowing for A&B Trials (JIS L 0855 Test: 95°C for 1 Hour and Cortrous Test: 50°C for 16 Hours):**

3. TUNE WHITE Features, Materials, Yarn Quick Reference

| Name | TUNE WHITE |

| Feature | Resistance to yellowing |

| Material | 100% nylon |

| Thickness (Dt) | 22Dt/2, 33Dt/2, 56Dt/2, 78Dt/2, 122Dt/2 |

| By order color quantity | 25kg ~ |

| Retail size | Depends on yarn |

| Color stock | – |

*Please note.

There may be differences between the colors you see on the web (on your computer monitor) and the actual colors.

The color samples (colorbook) featured on this page are intended for reference purposes only. For accurate color matching, please use our actual colorbook.